3 Simple Techniques For Premier Aluminum Llc

Table of ContentsSome Known Facts About Premier Aluminum Llc.Excitement About Premier Aluminum Llc8 Easy Facts About Premier Aluminum Llc DescribedThe 45-Second Trick For Premier Aluminum Llc

(https://www.goodreads.com/user/show/184481217-gary-martin)Making use of low expense and unqualified vendors can create quality issues, and lost time and cash in the lengthy run. To help you through the process, right here are some points to consider when choosing the best metal casting vendor.

A company that only makes use of the financial investment spreading process will certainly attempt to market you on why that procedure is best for your application (Casting Foundry). What if utilizing the sand casting process is best for you and your needs? Instead, look for a supplier that supplies a series of casting procedures so the very best choice for YOU is chosen

If working with a solitary resource for all of your casting requires is very important to you, the vendor requires to be diverse in its capacities. When integrated with other integrated capacities, this can assist simplify and press the supply base. When picking the right casting provider, mindful factor to consider ought to be offered to quality, solution, and price.

Rumored Buzz on Premier Aluminum Llc

Purchasers increasingly pick casting suppliers that have machining abilities. This can prevent problem if defects are uncovered during machining. If a 3rd celebration is machining, it may cause "finger-pointing" regarding that is at fault. Is it a casting problem or a machining issue? If the spreading provider uncovers a problem throughout machining, the issue is dealt with faster without dispute over whose mistake it is.

Trouble or no, integrated machining simplifies the supply chain and lowers managing time and delivery cost before the item makes it to the consumer. What do you need from your spreading vendor? Are you looking for someone to just deliver a steel part to your doorstep or do you need a lot more? As an example, if you do not have in-house metallurgy expertise, confirm that the vendor can give guidance in choosing the appropriate alloy based upon your specific application - Foundry near me.

Some shops are minimal or specialized. Make sure the supplier can meet all your material or alloy needs to eliminate the need for numerous distributors.

9 Easy Facts About Premier Aluminum Llc Explained

Research the vendor's website. Talk to a sales associate or business partner.

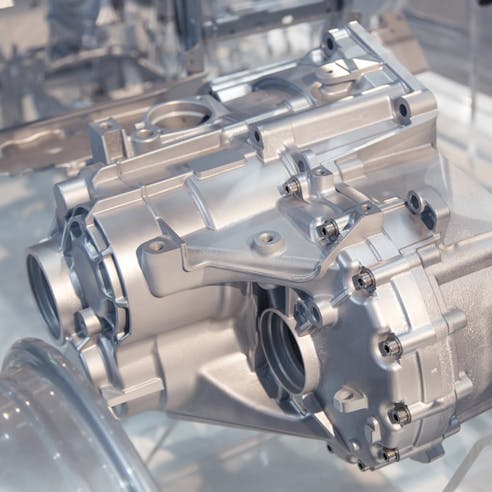

Aluminum is also lightweight and has excellent rust resistance, making it suitable for applications where weight and longevity are very important elements. In addition, aluminum casting is an affordable method of manufacturing, as it requires less power and sources than various other techniques. Iron casting, on the various other hand, involves putting liquified iron right into a mold to develop a preferred form.

Premier Aluminum Llc Can Be Fun For Anyone

Iron casting is also able to hold up against heats, making it suitable for usage in applications such as engine parts and industrial machinery. Iron casting can be much more costly than aluminum casting due to the greater cost of raw products and the power required to melt the iron. When determining in between light weight aluminum casting and iron spreading, it is necessary to consider the specific demands of the application.

In final thought, both aluminum casting and iron casting have their very own unique advantages and disadvantages. There are 3 sub-processes that drop under the classification of die spreading: gravity die spreading (or permanent mold and mildew spreading), low-pressure die spreading and high-pressure die spreading. To get to the finished item, there are three key alloys utilized as die casting material to choose from: zinc, aluminum and magnesium.